© 2025 bb&b communication et marketing industriel

Accueil > References > Yara Better Together

BETTER TOGETHER

Yara International

CLIENT

Yara International

TRADE

Chemicals

PROJECT

Better Together

TARGET

Internal

EXPERTISE

Change Management

Market

World

BETTER TOGETHER

Yara International

CLIENT

Yara International

TRADE

Chemicals

PROJECT

Better Together

TARGET

Interne

EXPERTISE

Change Management

MARKET

World

Need

The continuous improvement of operational processes (Kaizen, Lean Management) is a central issue for the competitiveness of companies. The aim of this project was to motivate employees for this topic and to create a corresponding working culture.

With more than 17,000 employees in 160 countries, Yara is one of the world’s leading producers of nitrogenous chemicals, especially fertilisers for agriculture. The Norwegian company thus makes a significant contribution to food security for the world’s population. Yara is also a successful and credible advocate of climate-friendly technologies in agriculture and transportation. The company thus plays a leading role in tackling two central problems facing humanity.

Approach

It was clear from the outset that a lasting commitment to continuous improvement (Kaizen) in the company could only be achieved through intrinsic motivation. The question was what intrinsic motivation could be based on.

During the development process, the idea came up to address the positive impact Yara is making on climate change and food security. Continuous improvements in the company’s processes thus translate into concrete benefits in the fight against the most serious threats humanity is facing. The individual contribution of each employee is thus transcended.

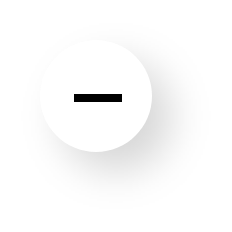

Implementation

The notion of “contribution” has been symbolically transposed into an original design concept. Individual contributions are represented by “tokens”. These tokens can be assembled to infinity and thus embody the contributions of everyone as well as the overarching objective and vision to achieve. This makes the idea of continuous improvement tangible.

Specific photography visually translates the concept into an invitation to participate.

Results

The concept is being deployed gradually in the company. It is so far positively received by employees.

Coworkers involved

0

Countries involved

0

Fertiliser production

0

p.a.